Industries

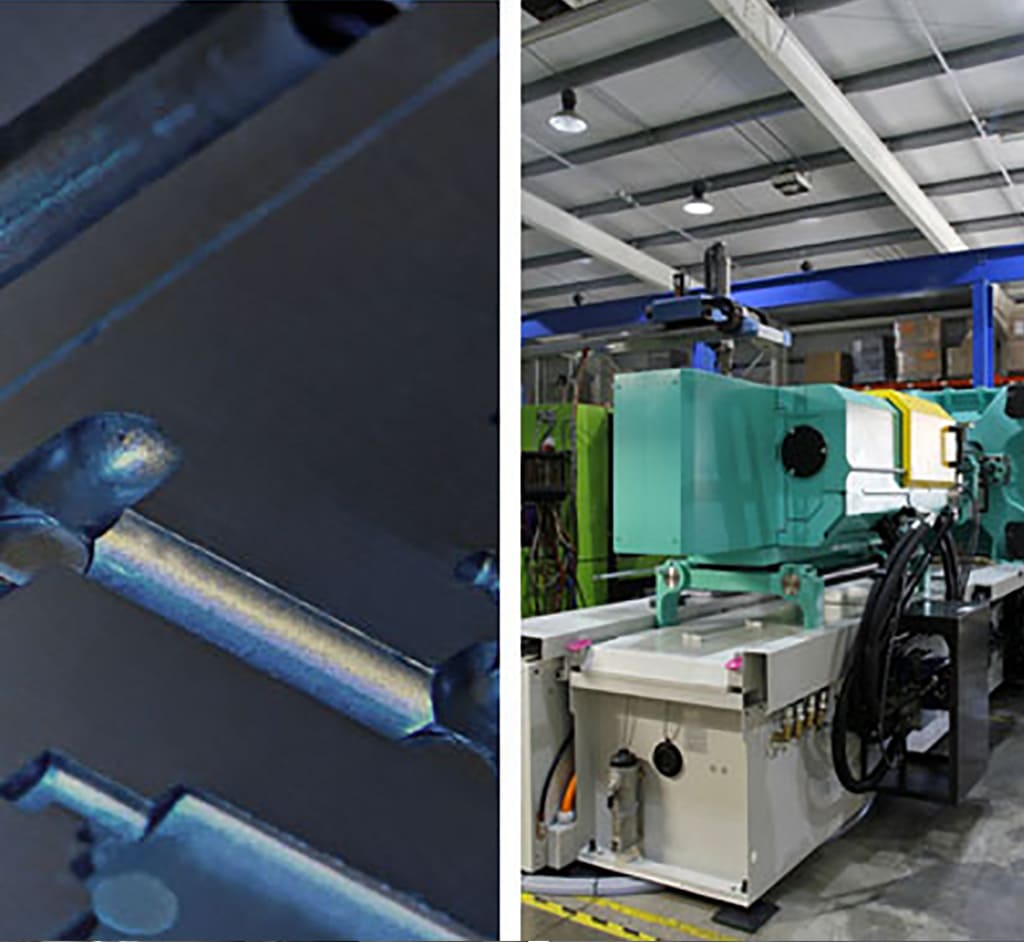

Moulding

Tool-Temp brings decades of experience to injection moulding customers.

Moulding medical products, Oxfordshire

This well-known Oxfordshire based high precision plastic injection moulding company specified ten TT-168 H 12 Kw high flow rate temperature controllers for individual temperature control of 10 4,500 Kg tools (2 controllers per mould). The units are mounted side by side on the back of the injection moulding machine, heating the tools to a maximum temperature of 90°C.

A further unit was ordered for the company to hold in stock as a spare, although this has not as yet seen service.

The Technical Manager selected the units for their accuracy of temperature control with the ability to process a high flow rate of cooling for a precise medical moulding application. The company also operates numerous Tool-Temp portable chillers to supplement the central cooling system and mould heaters that can be used for various individual applications.

PPS and PEEK moulding, South of England

A large manufacturer in the South West of England has standardised on Tool-Temp mould temperature controllers for two specific applications.

Moulding PPS material with a required mould temperature of 165°, two TT-288 8Kw oil heaters are used individually to heat the two halves of the tool. A TT-181 nit is configured for oil heating of the moving core fingers to 90°C.

On the company's PEEK Moulding machines, higher temperatures between 185°C and 210°C are needed. Two individual TT-288 units are used for this material as well.

Moulding Technicians at the company selected Tool-Temp units for their great reliability and accuracy of temperature control which is very critical with PEEK moulding.