Industries

Fibre & Textiles

Tool-Temp expertise provides precise and consistent control of temperatures in demanding roll applications.

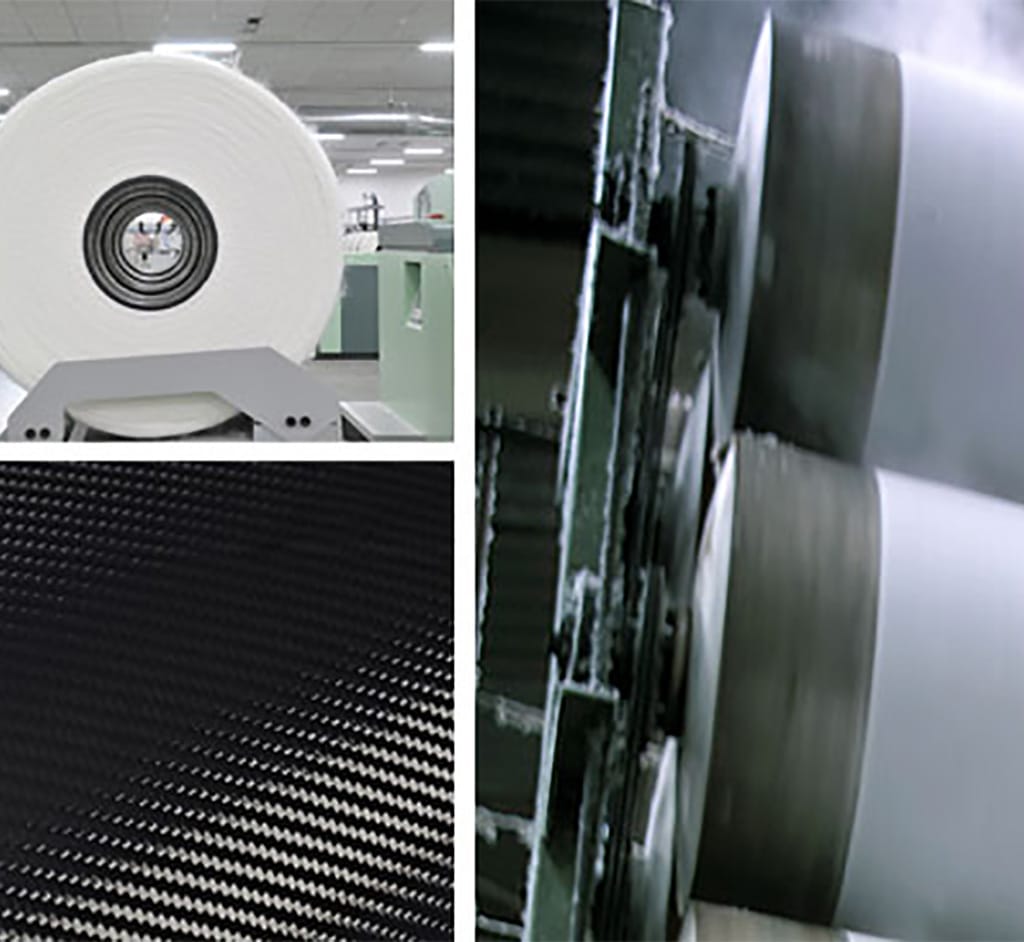

Carbon fibre pre-preg machinery

Tool-Temp were contacted by a Carbon fibre pre-preg machinery supplier based in the north of England to work alongside them supplying temperature control for roll applications requiring very close tolerances across the roll faces and around the rolls. Whilst temperatures were well within the Tool-Temp range due to the large surface area of the roll, a high flow pump was required.

A 48kW TT-500 unit was selected for the process with a pump capacity of up to 260l/min. The unit was also fitted with our fully interfaced profibus controller to allow ramped heating and cooling all of which is controlled via central Siemens system.

Since the first application we have now supplied several more lines to the customer and in all instances Tool-Temp worked very closely with the customer's Team to ensure that the equipment supplied was the most suitable to meet their processing requirements, and to give them the improvement on their processing conditions they required.

Textiles manufacturing

Tool-Temp has provided effective temperture control solutions for established leading UK textile manufacturer. Our engineers were called in to discuss oil heating for a large roll used in their fabric coating process. The roll surface temperature required was 185 ºc and due to the large surface area of the roll a high flow pump was required.

A 48kWTT-500 was selected for the process with a pump capacity of up to 260l/min. The unit was also fitted with an auto-start timer to facilitate automatic roll heat up prior to start up of production.

Sometime later a second line was installed again needing oil heating on two large rolls. On this occasion the most suitable units were the models TT-508 48kW and TT-708 72kW – again both with high flow pumps and capable of operating up to 300ºc.

On both occasions Tool-Temp worked very closely with the customers Operations Director to ensure that the equipment supplied was appropriate to their requirements, and provided the targeted improvements to their processes.