Pharmaceuticals

Precision control for diverse applications.

Precise temperature control is critical in pharmaceutical manufacturing processes to ensure product quality, process stability, and regulatory compliance

In applications such as double-walled vessels, accurate thermal management maintains consistent mixing and reaction conditions, preventing degradation of temperature-sensitive ingredients. Consistent heating or cooling helps achieve uniform batch quality and reproducibility, which are essential for maintaining the efficacy and safety of pharmaceutical products.

Precise temperature control is critical in pharmaceutical manufacturing processes to ensure product quality, process stability, and regulatory compliance. In applications such as double-walled vessels, accurate thermal management maintains consistent mixing and reaction conditions, preventing degradation of temperature-sensitive ingredients. Consistent heating or cooling helps achieve uniform batch quality and reproducibility, which are essential for maintaining the efficacy and safety of pharmaceutical products.

For moulded products, including capsules or medical-grade components, precise temperature regulation ensures consistent material flow, dimensional accuracy, and smooth surface finishes. Similarly, in laser cutting equipment used for tablet production, controlled cooling prevents overheating, which could otherwise alter material properties or compromise precision. Across all these applications, stable temperature control enhances process efficiency, reduces cycle times, and minimises waste.

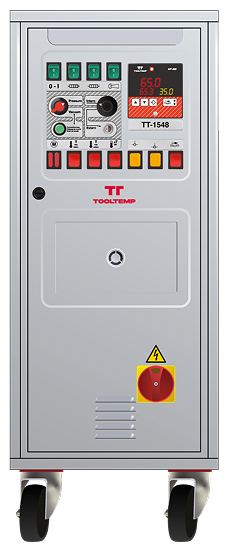

Tool-Temp temperature control units are perfectly suited to meet these demanding pharmaceutical requirements.

Their advanced design delivers exceptional accuracy, rapid response times, and consistent thermal stability across both heating and cooling phases. Built with durable, corrosion-resistant materials and a focus on cleanliness and reliability, Tool-Temp systems meet the stringent hygiene and safety standards of pharmaceutical environments. The units feature user-friendly controls, allowing operators to easily monitor and adjust process conditions, while their robust Swiss engineering ensures long service life and minimal maintenance.

With dedicated units, developed specifically for the temperature control of double-walled vessels, and a wide range to cover all applications, Tool-Temp temperature control units provide the precision, reliability, and efficiency essential for critical pharmaceutical processes—ensuring consistent product quality, operational safety, and compliance with the industry’s most rigorous standards.

Contact

For more information about our products or services, please contact us using the form and we will come back to you as soon as possible.