Injection Moulding

Tool-Temp brings decades of experience to injection moulding customers.

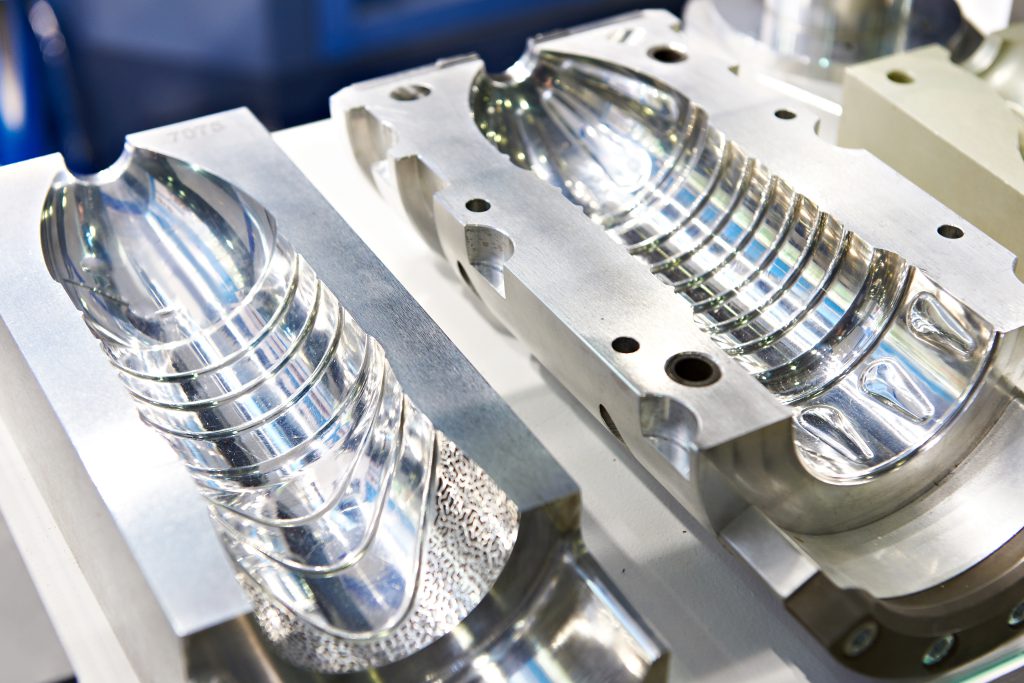

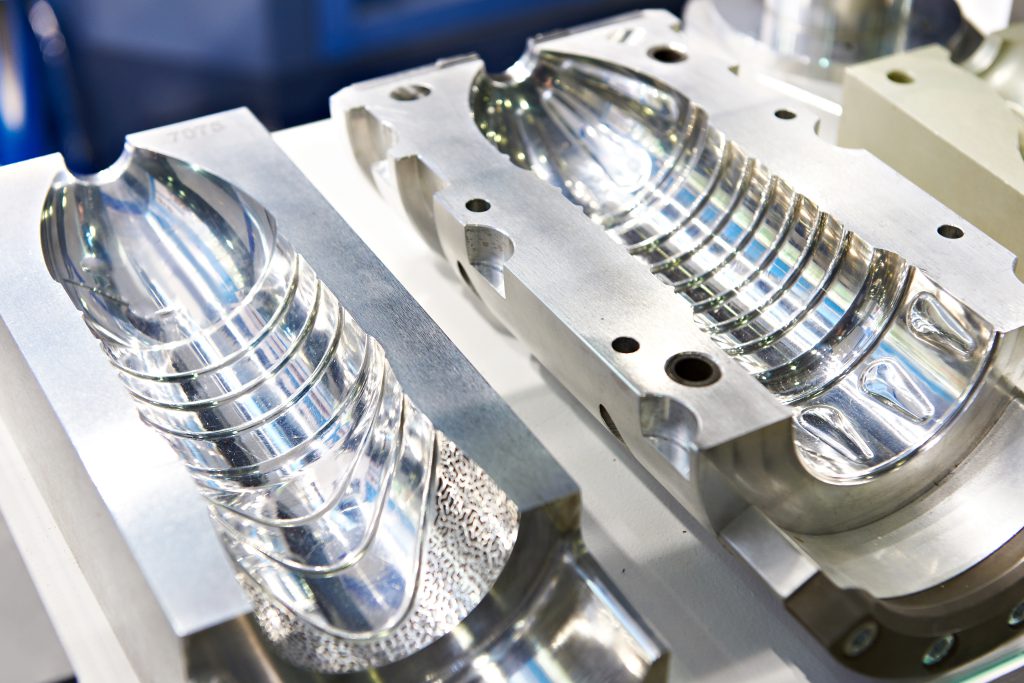

Precise tool temperature control is one of the most critical factors in the injection moulding process

The temperature of the mould directly affects material flow, cycle time, part quality, and dimensional stability. If the mould is too cold, it can cause incomplete filling, surface defects, or warping. Conversely, if it’s too hot, parts may suffer from flashing, deformation, or excessive cooling times. Consistent and accurate temperature management ensures that each moulded component meets tight tolerances, maintains uniformity across production runs, and minimises waste—ultimately improving efficiency and profitability.

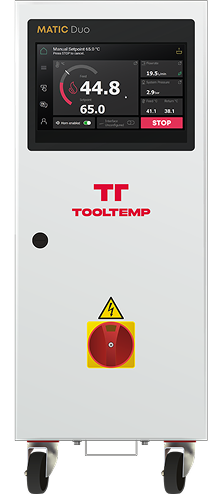

Tool-Temp temperature control units and chillers are ideally suited for maintaining the demanding thermal balance required in injection moulding. Their robust design ensures precise control of both heating and cooling cycles, allowing for stable mould temperatures throughout production. With accurate temperature regulation and rapid response times, Tool-Temp systems reduce cycle times and optimise energy use. They are engineered for reliability, featuring durable, corrosion-resistant components and simple, intuitive controls for easy operation and maintenance.

Furthermore, Tool-Temp units provide consistent performance across a wide range of applications and materials—from thermoplastics to high-performance polymers—making them versatile for various moulding environments.

Their advanced safety features, compact footprint, and proven build quality guarantee longevity and process stability. In short, Tool-Temp temperature control units and chillers offer the precision, reliability, and efficiency required to achieve superior part quality and repeatable moulding results, making them an essential investment for any modern injection moulding operation.

Tool-Temp temperature control units and chillers are ubiquitous in all injection moulding applications. With our wide range and their robust reliability and precise control, they are also the perfect choice for specialist processes, including high temperature, close tolerance, exotic materials like PEEK and the high standards required for Medical applications.

Contact

For more information about our products or services, please contact us using the form and we will come back to you as soon as possible.