Food & Beverage

Precision control – where quality is critical.

From dairy processing to brewing

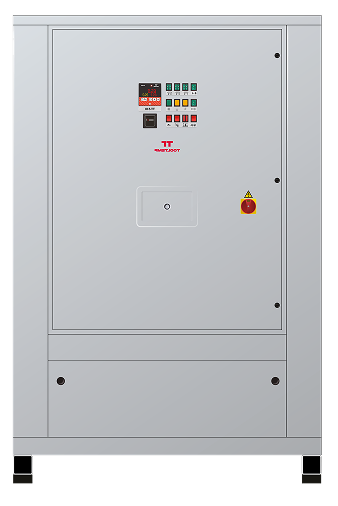

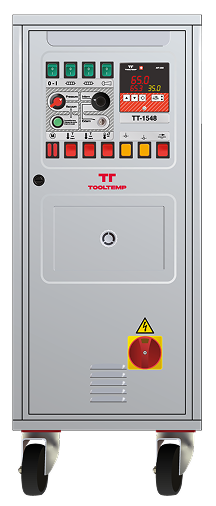

Tool-Temp’s temperature control units provide reliable, hygienic, and precise temperature management for a wide range of applications within the Food and Beverage industry. Built from corrosion-proof materials, these systems are designed to meet the strict cleanliness and hygiene standards essential in food processing environments. Their robust construction ensures long service life and consistent performance, even under demanding production conditions.

Temperature control plays a vital role across various stages of food and beverage production, from double-walled vessels used for heating, cooking, or mixing to chiller plants for refrigerated and cooling processes. Tool-Temp units maintain exact and stable temperatures, preventing issues such as overheating, crystallization, or contamination. This precision enhances product consistency, safety, and quality, while also improving process efficiency and reducing waste.

The standard Tool-Temp range is extensive and capable of meeting most food industry requirements, offering flexibility for a wide variety of processes.

For specialised needs, Tool-Temp’s engineering team can develop custom-designed systems tailored to unique production setups or specific temperature profiles. Additionally, we offer a dedicated range of units, developed specifically for the temperature control of double-walled vessels, ensuring optimal performance and hygiene in critical applications such as sauces, chocolate, dairy, and beverages.

With a focus on reliability, hygiene, and precision, Tool-Temp’s temperature control solutions support manufacturers in achieving consistent results, maintaining product integrity, and meeting rigorous food industry standards—all while providing durable, low-maintenance operation.

Contact

For more information about our products or services, please contact us using the form and we will come back to you as soon as possible.