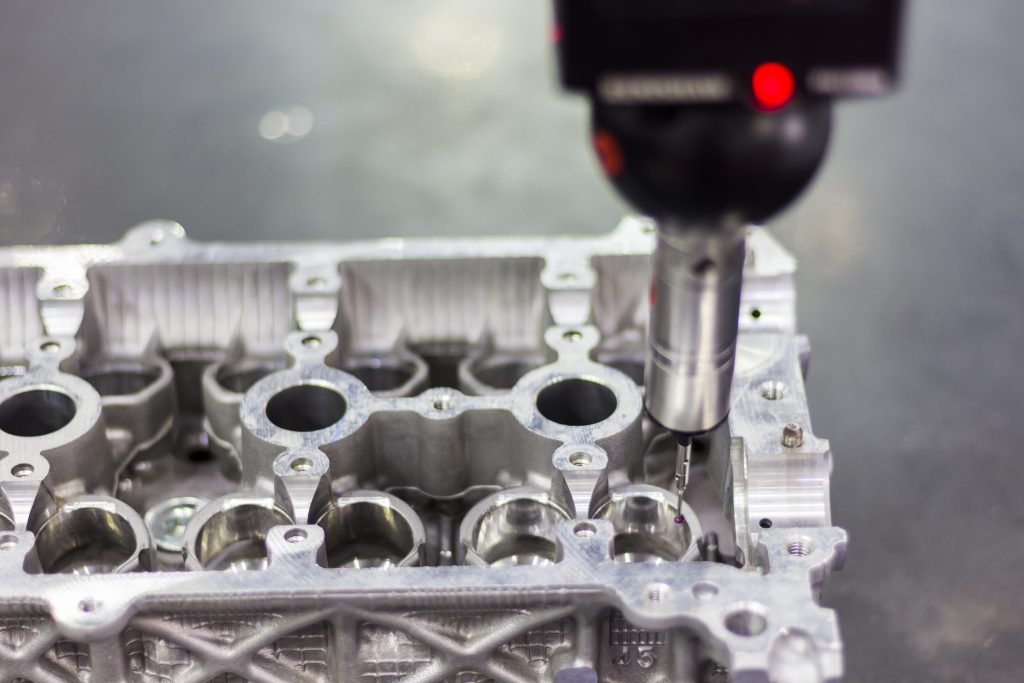

Die Casting

Specialised solutions for high temperature applications.

Tool-Temp recognise that maintaining a dynamic and closely controlled temperature in the die of a die-casting process is critically important for ensuring high-quality castings, long die life, and efficient production

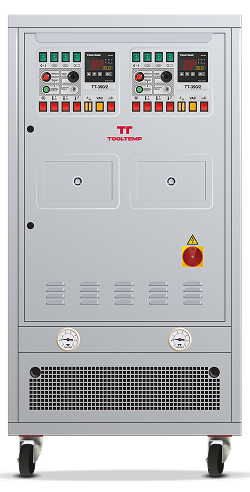

Typically alloys of Aluminium, Zinc, Magnesium and Copper are moulded, requiring high temperatures. Tool-Temp’s oil temperature control units provide the perfect solution for applications in die casting.

Initial Die Heating – Preventing Thermal Shock and Defects

Before starting production, the die must be preheated to a suitable temperature (often around 180–250°C depending on the alloy).

Our temperature control units can quickly bring the die to a stable working temperature where metal flow and solidification can occur predictably. The correct choice of temperature control unit can help prevent thermal shock, reducing the chance of cracking or warping of the die, as well as helping to avoid incomplete filling, cold shuts, or misruns. Your Tool-Temp can also help provide uniform cooling, reducing the risk of poor surface finish and dimensional inaccuracies in the final casting.

Controlled Cooling – Managing Heat Build-Up

Once casting begins, each shot introduces a large amount of heat into the die. As well as heating, the temperature control unit will need adequate cooling capacity to bring this temperature down at the rate you require, to a controlled temperature. Your Tool-Temp will remove heat and control consistently to help avoid flashing (metal leaking at parting lines), soldering (metal sticking to die surfaces) and dimensional distortion. It can also help to reduce cycle times.

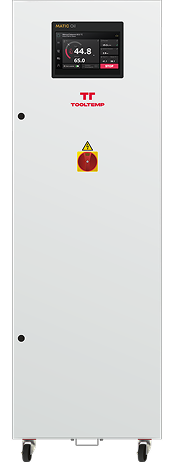

Dynamic Temperature Control – Adapting During the Process

The die temperature changes dynamically during each cycle. Therefore, a dynamic and precise temperature control system is essential to ensure consistent casting quality from shot to shot.

Tool-Temp can help you maintain uniform temperature distribution to prevent hot spots and uneven shrinkage or give localised control for complex parts.

Contact

For more information about our products or services, please contact us using the form and we will come back to you as soon as possible.